A Feet Warmer

The concrete floor was cold, so I wanted a heater to keep my feet warm under a workbench. I tried a standard portable heater, but it had two problems:

- The standard heater's thermostat alternately roasted and froze my feet.

- The standard heater could not be used when I used the soldering iron at the same workbench or the circuit breaker would trip.

The problem is that nobody sold a heater that puts out less than 500 watts. So I made one:

The calculations I used are as follows:

|

Heater calculations: Calculations at 240 Volts: 500 W / 240 V = 2.0833 A 240 V / 2.0833 A = 115.2 Ω

This heating element is ohmic, meaning it does not change resistance with

changes in temperature.

Calculations at 120 Volts: 120 V / 115.2 Ω = 1.0417 A 120 V × 1.0417 A = 125 W

125 W = 125 J/s cv,air = 1 KJ/Kg/°C cbed = 20 KJ/bed/°C Warmer temp = Tht = 116°F = 46.7°C Over the warmer temp = Toh = 99°F = 37.2°C Ambient air temp = Tam = 80°F = 26.7°C Mattress temp = Tmt = (Tam + Toh) / 2 Tmt = (80°F + 99°F) / 2 Tmt = 89.5°F = 31.9°C

CPSC SPACE HEATER STANDARD USUALLY CAN'T BE OBEYED The CPSC rule requires a circle of empty space at least 6 feet in diameter with the heater in the center. Very few places have such a space available. Most homes could not have even half of that space available. This seems to be an overkill standard with parameters chosen by bureaucrats to keep space heaters from being used. The standard was designed for the worst case (1500 Watt heater), but written to be a one-size-fits-all standard. It is overkill for small heaters. |

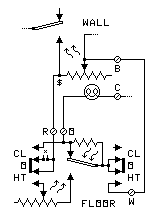

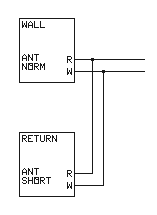

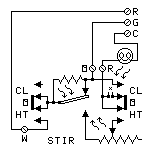

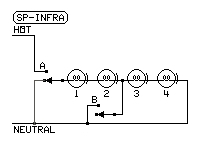

I bought a 500 watt 240 volt baseboard heater and put a 120 volt plug on it, as shown at right. Make sure the hot wire goes to the thermal fuse. The calculations show that the heater is now a 125 watt warmer. This warmer does not draw enough current to cause problems when the soldering iron was in use. The warmer worked just as I wanted it without a thermostat. When I later wanted to adjust this kind of warmer's output, I found that an ordinary lamp dimmer worked quite well. The thermal fuse prevents the warmer from overheating. Because of the shape of the case, I had to use the warmer upside down so it could be set flat on the floor. |

Wiring diagram of a 240 V

|

||||||||||||||||||||||||

|

This can also be used under a bed, as it does not make enough heat to cause a hazard

|

DEFINITIONS: Joule (J) - The metric unit of energy. 1 joule = 1 watt second cv = Coefficient of specific heat cv,air = 1 KJ/Kg/°C This means that it takes 1000 joules of heat to increase the temperature of a kilogram of air by 1°C. About 1 Kg of air is under a bed. cv,bed = 20 KJ/bed/°C This means that it takes 20000 joules of heat to increase the temperature of the bed by 1°C. The entire bed is the thermodynamic element. The 20 KJ is an average.

CONVERTED

- Power used: 125 W

COMPARE TO

- Power used: 200 .. 400 W

COMPARE TO

- Power used: 120 W

|